Electrical Signaling Systems & Units

MINE HEALTH AND SAFETY ACT, 1996 (ACT No. 29 OF1996) (Amendment No. R 1225 - Dec 2005)

REGULATIONS RELATING TO MACHINERY EQUIPMENT - CHAPTER 8

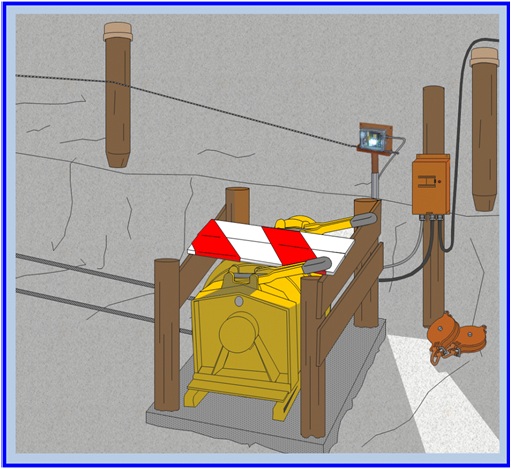

Scraper Winch and Mono-Rope Installation

8.4(2) The measures to be taken by the employer in terms of regulation 8.4(1) must include measures to ensure that-

(a) scraper-winches and mono-rope winches are only operated by competent persons authorized by the employer to do so;

(b) the scraper winch or mono-rope winch is not operated until it is examined and declared safe to operate by a person authorised to do so by the employer;

(c) means are provided to forewarn persons of the intention to commence operating any scraper-winch or mono-rope winch; (PRE-WARNING)

(d) means are provided for persons to signal to the operator, from any access point to the installation, to shut down the operation of the scraper-winch or mono-rope winch installation; (SAFETY CUT-OUT)

(e) scraper winch and mono-rope winch ropes, scraper attachments and rope splicing are regularly inspected;

(f) the scraper winch ropes are always underlay;

(g) a written procedure is prepared and implemented for the installation of the winch system

LOW COST ELECTRICAL WINCH Signaling System

This System will Visually and Audibly PRE-WARN when it is switched on to warn anybody in the Scarper Path that scraping operations are about to commence

Extension Units can be added to the system and installed at ANY customer required intervals as to ensure SAFETY AWARENESS and complete coverage of the Scraper Path

AN UNCOMPLICATED, EXTREMELY COST EFFECTIVE SYSTEM THAT WILL ENSURE COMPLIANCE TO DME REQUIREMENTS FOR WINCH SIGNALLING INSTALLATIONS

Click on the product picture to open the detailed Information Pamphlet of that product in another window or right-click and click "Save Target As" to save a copy to your computer

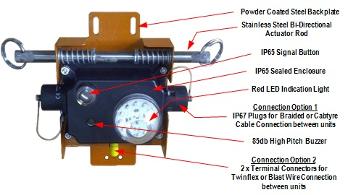

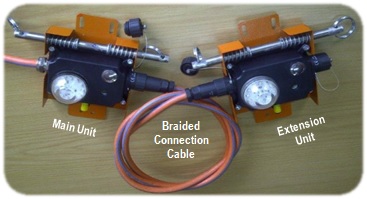

This System consists of three main components:

- A Main Unit that is connected to the existing winch stop/start box (plugs into the 24V or 32V auxiliary power supply plug of the existing winch stop/start boxes - no additional transformers or changing of starter boxes is necessary)

- Extension Units that can be installed at any required intervals to cover the complete scraper path.

- Extension Cables or Wires (depending on the customer's Inter Connection requirements)

Connection Option 1 - IP67 Plugs

a) High Cost Braided Connection Cables to customer specified length fitted with 2 x IP67 Connection Plugs

b) Low Cost Cabtyre Connection Cables to customer specified length fitted with 2 x IP67 Connection Plugs

Connection Option 2 - Terminals

a) Very Low Cost Twinflex or Blasting Wires which can be connected between any terminal connector

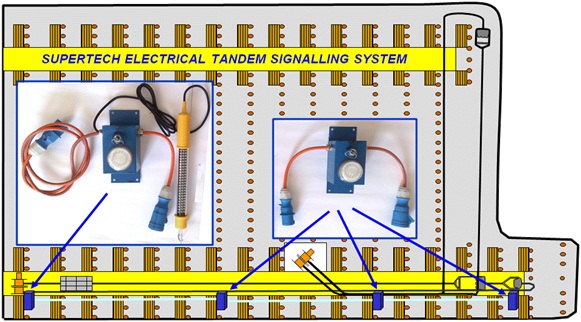

Electrical Tandem Signaling System (WINCHKIT SYSTEM)

Eliminate Unsafe Acts or Production Loss Due To Faulty or Inactive Signalling Units at the Scraper Winch

Click on the product picture to open the detailed Information Pamphlet of that product in another window or right-click and click "Save Target As" to save a copy to your computer

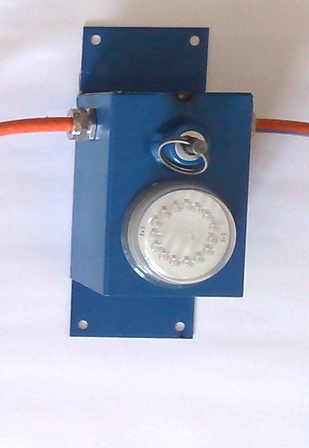

Electrical Safety Cut-Out & Communication Signaling System

Electrical Safety Cut-Out Winch Signaling Unit